Aerospace

Anti-Icing

In many industries such as aerospace, ice build-up and deposits can cause serious problems. For example, a thin layer of frost that settles on an airplane's wings can affect the aerodynamics of the airplane, ultimately leading to increased fuel consumption, reduced lift and increased drag. Anti-icing and de-icing measures are carried out on the ground using up to 600 liters of hot chemicals and in flight using fuel to heat aircraft parts.

These previous methods can be very complex, expensive and environmentally harmful.

With our innovative laser technology, potentially multiple advantages can be made possible: less environmentally harmful de-icing agents are required, waiting times for passengers are reduced and energy and fuel consumption are reduced, as is the flight weight as a result of smaller heating units.

Advantages

Our DLIP approaches can offer several advantages over traditional prevention measures:

- Reduced ice formation to partial spontaneous ice shedding under certain conditions (video)

- Reduction of the thermal heating power in electrothermal de-icing of surfaces by up to 80%

- Reduction of thermal output with anti-icing by up to 60%

Why our solution?

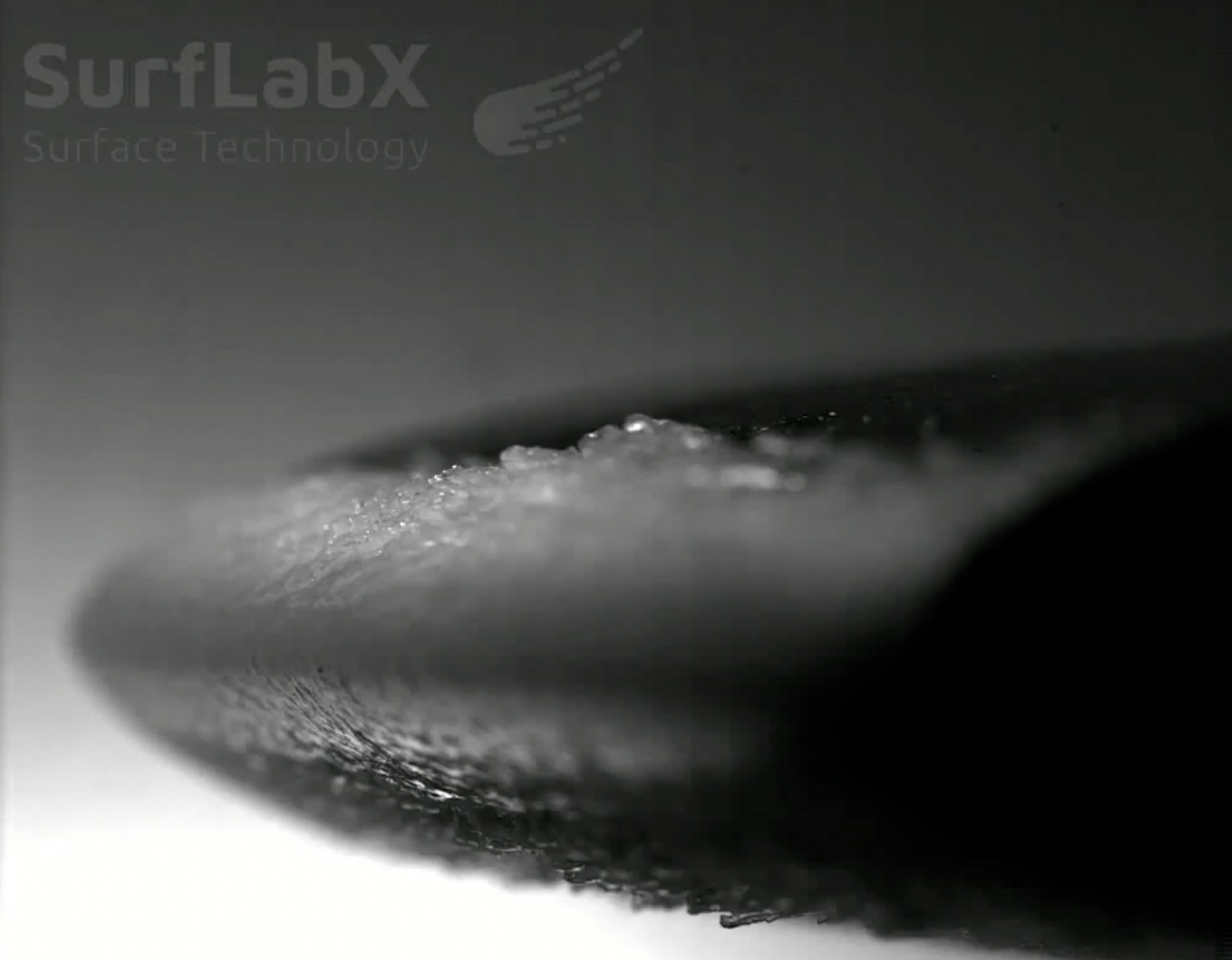

The application of functional laser structures to wings, wing segments and other surfaces affected by ice can contribute to a possible protective mechanism.

- Non-contact processing

- Precise energy input

- Flexibility in surface design

- Low environmental impact

While several laser approaches are already available on an industrial scale, with DLIP we offer a completely different solution as a new standard for surface functionalization.

Appropriate test setups have already been successfully implemented by us during our time at Fraunhofer, - together with the Technical University of Dresden and AIRBUS.