Discover the future of functionalized surfaces with our bio-inspired laser textures. Suitable for the automotive industry, aerospace, medical technology and much more.

Awards & Nominations

Inspired by nature

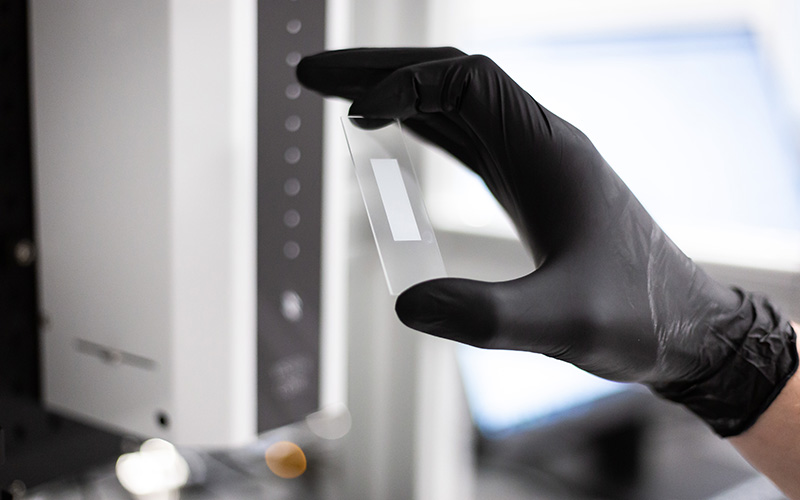

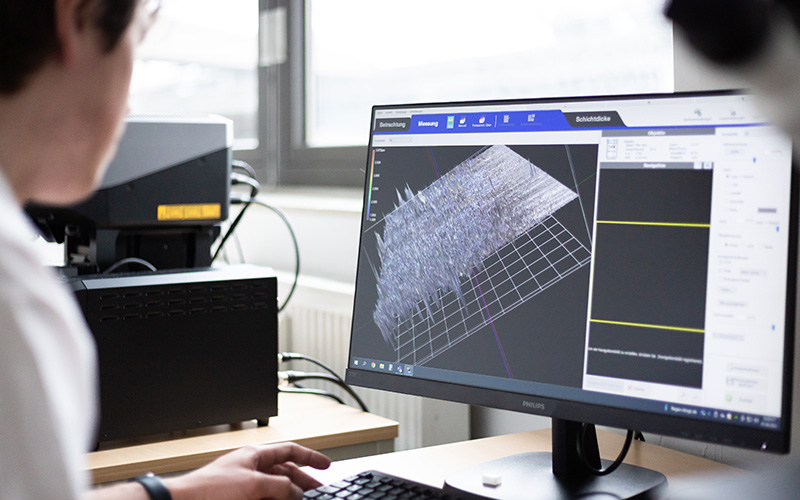

After 10 years of joint and intensive cooperation between the Fraunhofer Institute for Material and Beam Technology IWS and the Technical University of Dresden, we offer a unique solution to improve the surface performance of products, applications and components using our new standard: DLIP - Direct Laser Interference Patterning.

Our engineered solution is inspired by natural surfaces such as the lotus leaf, sharkskin, collembola and morpho butterfly, which allows for advanced surface features such as self-cleaning, anti-icing, antibacterial, decoration, drag reduction and more. We transfer these diverse effects to technical surfaces through laser-based surface functionalization.

Industrial applications

Aerospace

The use of laser-based functional surfaces can lead to numerous advantages and cost savings in the aerospace industry. These include improved anti-icing behavior, reduced energy consumption for de-icing and reduced noise pollution.

Instead of coating or foiling surfaces as before, functional microstructures can be textured directly into the surface using a laser.

In this way, time-consuming maintenance work and expensive new purchases can be avoided.

Automotive industry

There are numerous savings and improvement potentials in the automotive industry.

Reduced friction between surfaces, reduced wear, longer lubricant life, or reduced contact resistance between electrical connectors are just some of the benefits of our DLIP method.

This means that established, cost-intensive or complex process steps can be partially replaced.

Medical technology

There is huge potential in medical technology.

Healing times, quality of life and well-being can be decisively improved through improved biocompatibility of implants, tailor-made wettability, non-stick effects and antibacterial functionalities.

In addition, the surface improvement of medical components reduces costs in the long term.

More applications

Our functionalized surfaces are also widely used in other areas such as energy generation, production processes and in the consumer sector.

The topics of glass finishing, cost reduction in mechanical manufacturing processes, resistance to environmental influences and increased performance of energy systems play a major role here.

Fast, flexible, functional

- No clean room or vacuum required

- No additional chemicals required

- Extremely high process speed

- Functional surfaces in one process

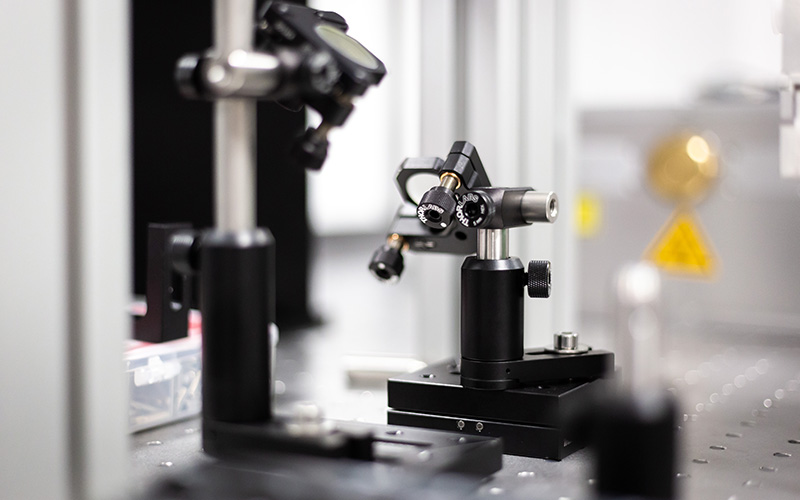

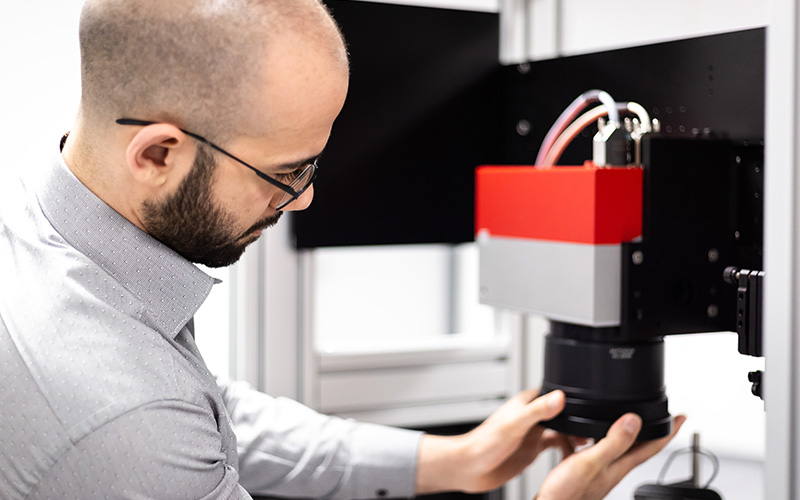

CORE series

Highly flexible interference modules

- Modular solution for surface functionalization

- Wavelengths from IR to UV

- Various pattern geometries

- Structure sizes from 0.5 to 12.0 µm

- Structural features adjustable via software

- Decoration

- Holograms & Matting

- Light control

- Self cleaning & wetting

- Biocompatibility

CORErapid Series

Scanner-based interference modules

- Modular solution for high-speed surface functionalization

- Wavelengths from IR to UV

- Various pattern geometries

- Structure sizes from 1.5 to 30.0 µm

- Structural features adjustable via software

- Decoration

- Holograms & Matting

- Light control

- Self cleaning & wetting

- Biocompatibility

COREultra Series

Highly flexible interference modules

COMING SOON…

- Modular solution for surface functionalization

- Wavelengths from IR to UV

- Various pattern geometries

- Structure sizes from 0.5 to 12.0 µm

- Structural features adjustable via software

- Decoration

- Holograms & Matting

- Light control

- Self cleaning & wetting

- Biocompatibility

Let's develop your full potential together!

Let's develop your full potential together!

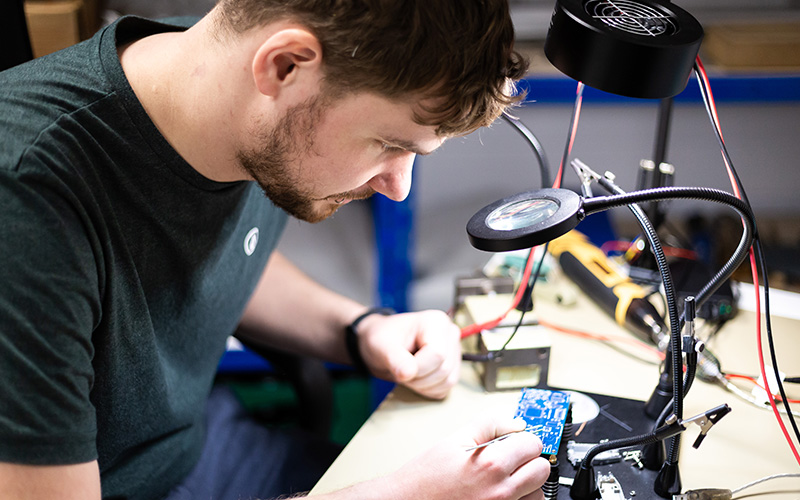

Consulting

Take advantage of more than 20 years of experience in laser surface functionalization.

Individual solutions

We advise and support in process development and optimization.

Integration

Integrate our advanced laser technology into your existing production lines and developments with the help of our experts.

R & D cooperation

Work with our specialists to push the boundaries of possible surface effects in joint R&D projects.

Production

Save investment costs by using our ready-made solutions.

Training & Support

Train your employees, either at your site or in our application center.

Founder

As a spin-off of the Fraunhofer IWS, we founded Fusion Bionic GmbH in April 2021 with a team from science and industry.

With more than 20 years of experience in using advanced laser technologies, we are redesigning the performance of numerous products.

We draw on unique expertise consisting of surface know-how, sophisticated system technology and the passion to get the most out of every surface.

Dr. Tim Kunze

Chief Executive Officer

Laura Kunze

Chief Financial & Operation Officer

Dr. Sabri Alamri

Chief Research Officer

Benjamin Krupop

Chief Technical Officer

Fusion Bionic stands for the combination of nature-inspired effects in technical product surfaces. Following the example of bionics, we create a symbiosis of technology and biology.

Career

Shaping the future together. We are always looking for talented applicants.

Our complete job offer can be seen on our career portal.

"Great things in business are never done by one person. They´re done by a team of people."

News & Events

and press releases can be found on our blog.

Fusion Bionic wins Fraunhofer Founder Award 2024

Dresden, 19.02.2025 - Fusion Bionic, a leading company in the field of laser-based surface functionalization, has been honored with the Fraunhofer Founder Award 2024.

Welcome to the 1st Bionic Laser Forum from Fusion Bionic!

Mit großer Vorfreude und Enthusiasmus heißen wir Sie am 29. November 2023 in Dresden, Deutschland, zum 1. Bionic Laser Forum

Fusion Bionic Announced as Ray of Hope Prize Runner-up 2022

The Biomimicry Institute awards Fusion Bionic with Runner-up recognition in 2022 Ray of Hope Prize®. This identifies Fusion Bionic